Step 1.

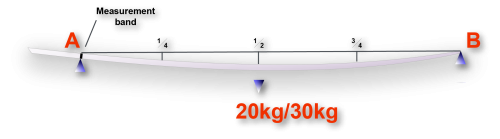

Divide the mast into 4 sections (with 3 stripes) or 8 sections (with 7 stripes) of equal length between the gooseneck measurement band and the mast top measurement band.

Step 2.

Support the mast at the gooseneck band and the masttop band on a pair of sturdy supports. For backbend measuring let the gooseneck point upwards. For sidebend place the gooseneck at 0 degrees/ horizontal. Mark the mast at even spacings along the length of the mast between the bands.

Step 3.

Hang a weight (preferably 20kg or 30kg, but not really important) at the mid point of the mast (1/2 point)

Step 4.

Tension a thin string between the two measurement bands, shown above as points A and B.

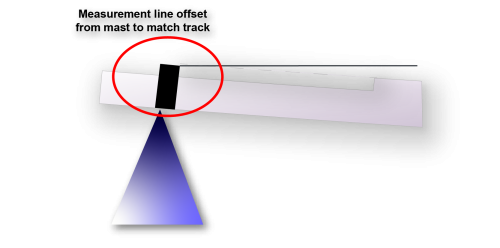

For each type of mast a spacer may need to be used to bring the reference line away from the non-sailtrack profile. For the Ceilidh Composites FD profile this is 12mm and for the MR profile 10mm.

This spacer should be placed between the mast and the string at point A.

Step 5.

Measure the perpendicular (at 90degrees) distance from the lowest point of the mast at each measurement point to the lower surface of the tensioned line. Record these figures in the provided measurement form.

This form is suitable for use for the bend curves of all stayed masts that Ceilidh Composite Technologies manufactures.

Step 6.

To measure the side bend, the mast should be rotated 90° on the supports, and the line at the two bands (A & B) should be moved to the middle of the sail-track opening.